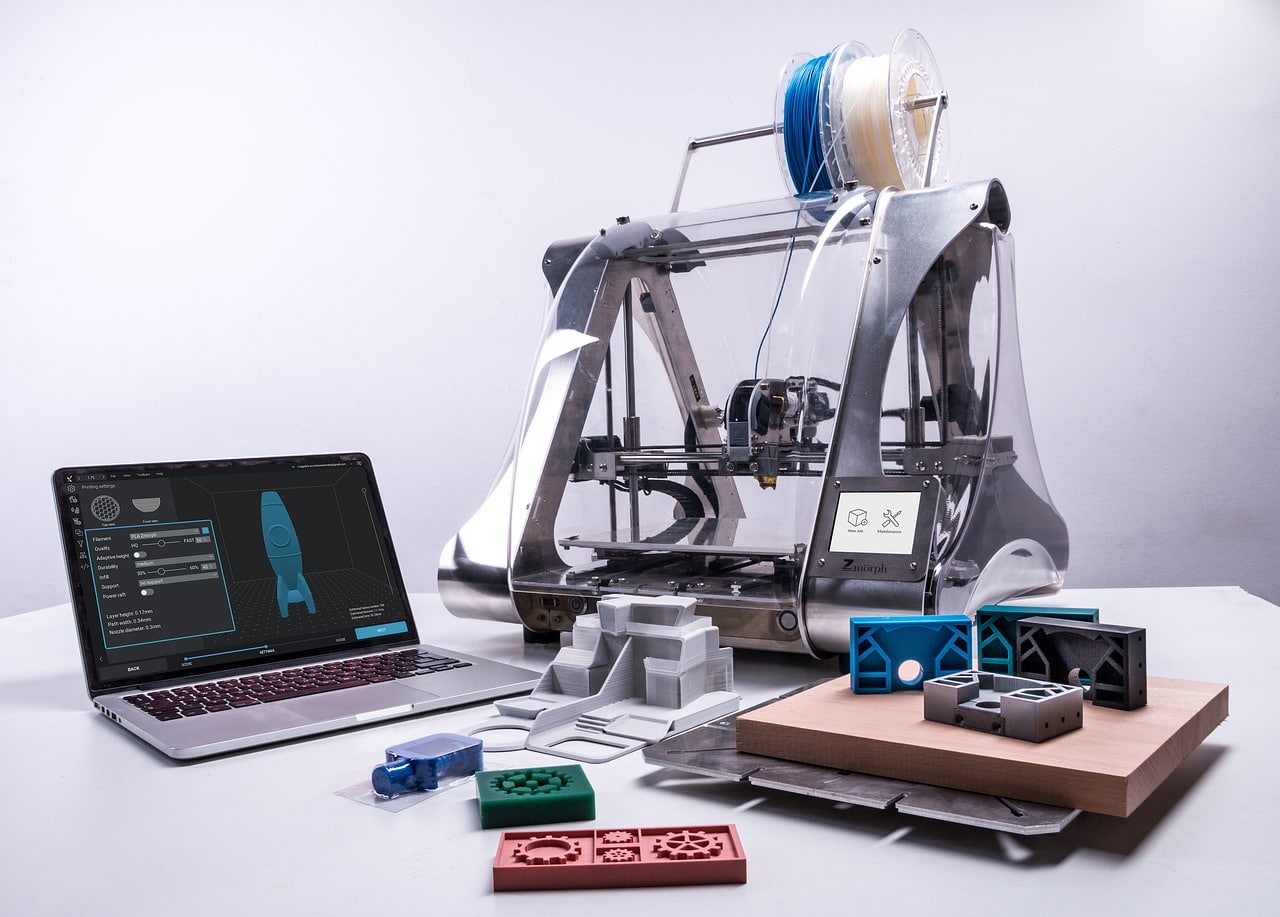

Un prototype It is an initial version of the idea of a product or service. A necessary step prior to its official launch with which we can test, evaluate and validate an idea or project. With the emergence and development of 3d printing service, the way to create prototypes has taken a gigantic leap. Now it's easier, faster and much cheaper. A whole revolution.

The importance of the prototype within the process of creating any idea is basic. With it, we are going to have a physical tool that will help us verify that our idea makes sense beyond the theory on paper. It will also help us to find out if there really is a market and a demand. Estimate production costs, carry out tests among potential users, etc.

Currently there are many processes that can be used for prototyping. Some of the best known are CNC machining or injection molding. In the case of 3D rapid prototyping is additive manufacturing technology the one that is used

Advantages of 3D rapid prototyping

3D printing has great advantages when making prototypes of parts, products, etc. These are the most important:

- Allows the creation of unique and complex shapes. You can go as far as classical prototyping methods do not.

- The process is very fast. It takes just a few days instead of weeks, which is typical using traditional methods.

- Provides significant cost savings. With 3D printing technology, it is not necessary to modify molds or change machinery when we decide to change the design of our prototype. They are costs that are avoided.

- Generate less waste, since additive manufacturing technology only uses the necessary material. In contrast, in the traditional method, excess material is removed to create the part, which obviously produces more waste.

Thanks to these and many other advantages, The use of 3D printing technology is spreading unstoppably.e, covering all kinds of sectors beyond those strictly linked to industrial processes. A good example of this is in the health sectoror, where it is used successfully for the production of prostheses, implants and other elements.

Types of 3D printing technology

When manufacturing prototypes using 3D printing, it is very important assess which technology is the most appropriate. The correct choice will depend on the peculiarities of each specific case. In general, there are three possibilities:

- molten material deposition (FDM).

- Selective photopolymerization of resins (SLA).

- Selective laser sintering (SLS).

SLS, for example, offers a higher degree of precision than other technologies; on the other hand, the FDM allows a more versatile production, since it can use a greater variety of materials and, above all, faster.

A technology for the future

It is spectacular to look back and see the extent of the progress made in recent years in terms of 3D printing. In just a few years we have gone from having a technology in its infancy to achieving the production of highly complex and high quality parts.

And yet we are still witnessing the first steps of this revolutionary technology. 3D printing today allows the production of prototypes, but also the manufacture of final designs with industrial quality finishes. A technology that in the future will contribute solutions for almost any application imaginable.